MBU-Micro Bore Units

- Precision Finish Boring Unit with high accuracy & repeatability.

- Used for machining close tolerances.

- Facilitates precision adjustment with least count of 1 micron (0.001mm) radially.

- Can be mounted in blind holes with provision of adjustment from the top.

- Self-clamping / Self-locking units i.e., no tightening & loosening of screws involved.

- Pre-loaded (pre-tensioned) assembly guaranteeing practically “Zero” Backlash.

- Minimum diameter for finish boring is 19mm.

- Adjustment can be done directly while the tool is on the machine, thus reducing downtime or setting time.

- Standard products (88 variants) available for ID boring, back boring, OD turning and undercut machining applications.

- Directly interchangeable with FA & FV fine boring units or equivalent.

-

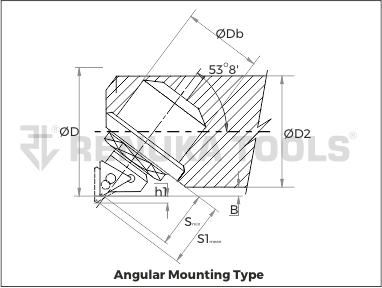

Angular Mounting Type

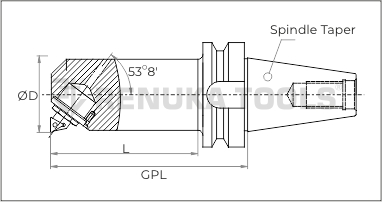

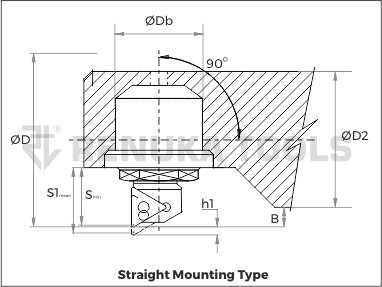

- Straight Mounting Type

- Customized Micro Bore Units

- Applications

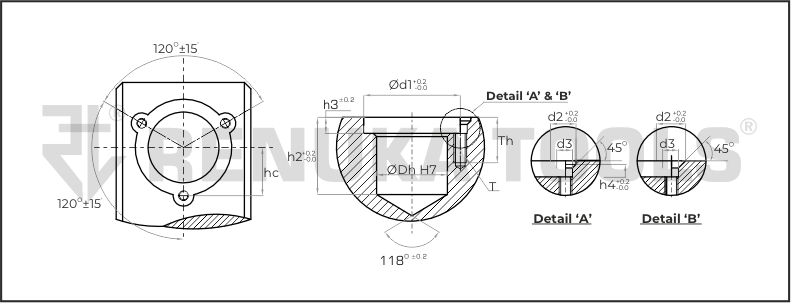

- Mounting Dimensions for Micro Bore Units

- Working Dimensions for MBU

- Operating Instructions

- Precautionary Measures

MBU - Angular Mounting Type

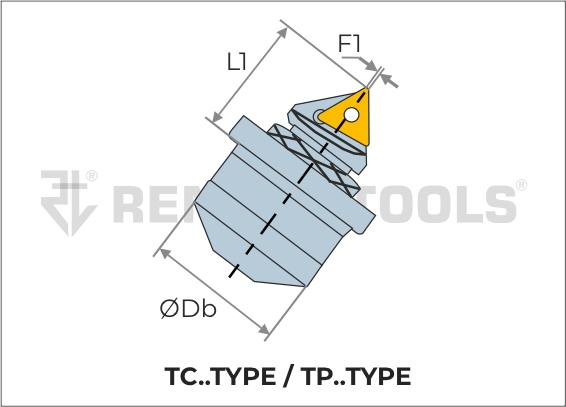

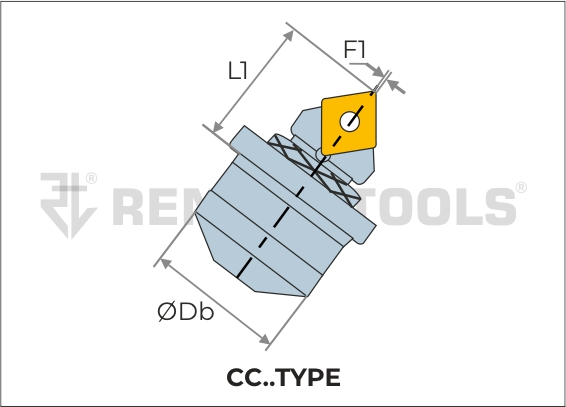

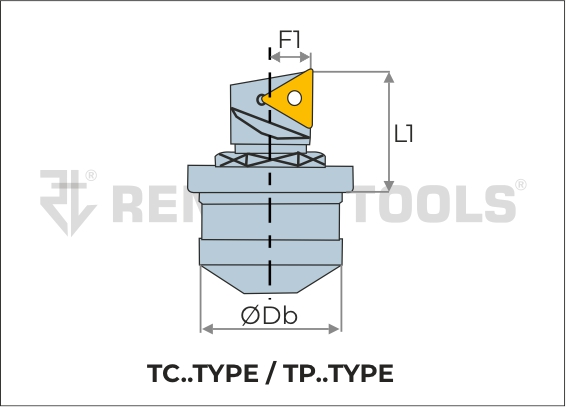

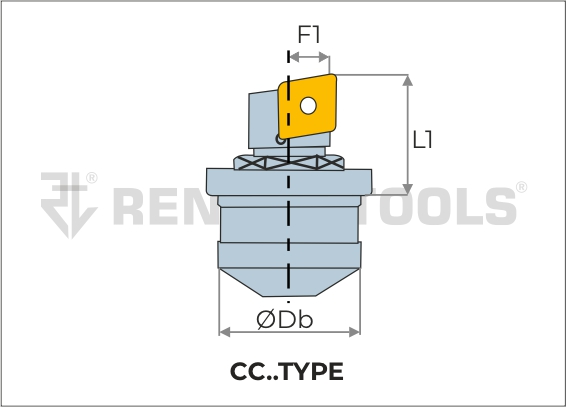

| sr no | Item Code | Insert | Db | L1 | F1 | Dmin | Mounting Screw | Insert Screw | Torx | Spanner | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LH | RH | ||||||||||

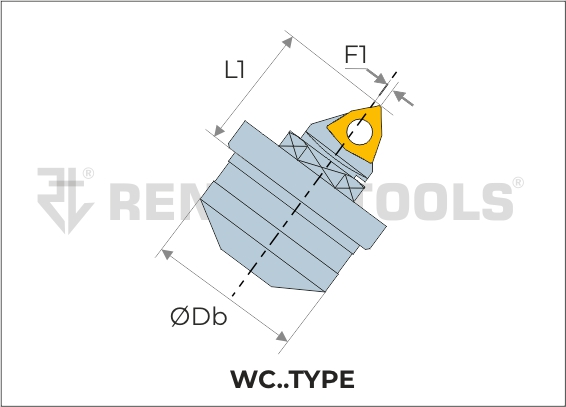

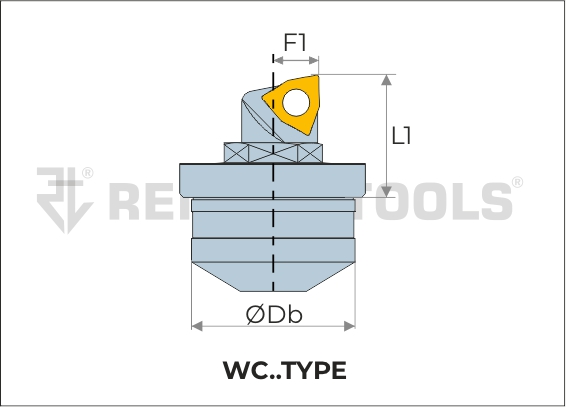

| 1 | RT MBU ALW 02 14 | RT MBU ARW 02 14 | WC..0201.. | 14 | 11.50 | 1.00 | 20.00 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 2 | RT MBU ALC 04 14 | RT MBU ARC 04 14 | CC..04T0.. | 14 | 11.50 | 1.00 | 20.00 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 3 | RT MBU ALT 06T1 14 | RT MBU ART 06T1 14 | TC..06T1.. | 14 | 11.50 | 0.20 | 20.00 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 4 | RT MBU ALT 0601 14 | RT MBU ART 0601 14 | TC..0601.. | 14 | 11.50 | 0.20 | 20.00 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 5 | RT MBU ALC 06 16 | RT MBU ARC 06 16 | CC..0602.. | 16 | 14.30 | 0.45 | 25.90 | RTMS16 | M2.5 | T8/T10 | RTS16 |

| 6 | RT MBU ALT 06T1 16 | RT MBU ART 06T1 16 | TC..06T1.. | 16 | 14.30 | 0.20 | 25.40 | RTMS16 | M2.0 | T6/T10 | RTS16 |

| 7 | RT MBU ALT 0601 16 | RT MBU ART 0601 16 | TC..0601.. | 16 | 14.30 | 0.20 | 25.40 | RTMS16 | M2.0 | T6/T10 | RTS16 |

| 8 | RT MBU ALC 09 20 | RT MBU ARC 09 20 | CC..09T3.. | 20 | 19.10 | 1.00 | 33.10 | RTMS20 | M3.5 | T15/T10 | RTS20 |

| 9 | RT MBU ALT 09 20 | RT MBU ART 09 20 | TC..0902.. | 20 | 19.10 | 1.00 | 33.10 | RTMS20 | M2.2 | T7/T10 | RTS20 |

| 10 | RT MBU ALTP 09 20 | RT MBU ARTP 09 20 | TP..0902.. | 20 | 19.10 | 1.00 | 33.10 | RTMS20 | M2.5 | T8/T10 | RTS20 |

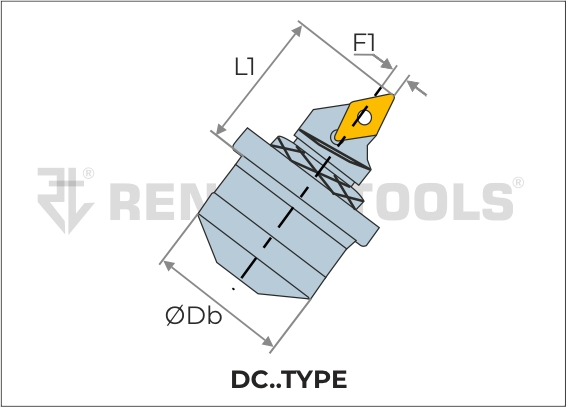

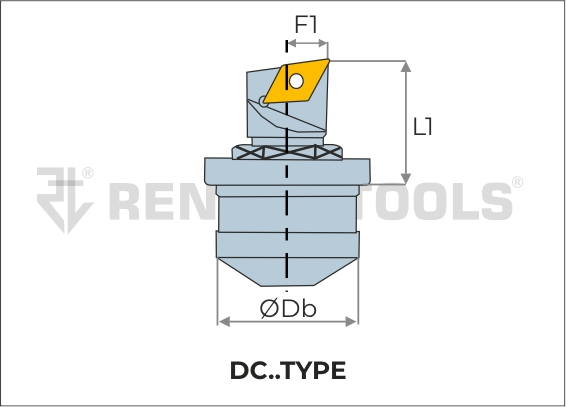

| 11 | RT MBU ALD 07 20 | RT MBU ARD 07 20 | DC..0702.. | 20 | 19.10 | 1.00 | 33.10 | RTMS20 | M2.5 | T8/T10 | RTS20 |

| 12 | RT MBU ALC 09 22 | RT MBU ARC 09 22 | CC..09T3.. | 22 | 23.00 | 1.10 | 42.60 | RTMS22 | M3.5 | T15 | RTS22 |

| 13 | RT MBU ALT 1102 22 | RT MBU ART 1102 22 | TC..1102.. | 22 | 23.00 | 1.10 | 42.60 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 14 | RT MBU ALT 1103 22 | RT MBU ART 1103 22 | TC..1103.. | 22 | 23.00 | 1.10 | 42.60 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 15 | RT MBU ALTP 11 22 | RT MBU ARTP 11 22 | TP..1103.. | 22 | 23.00 | 1.10 | 42.60 | RTMS22 | M3.0 | T10/T15 | RTS22 |

| 16 | RT MBU ALD 07 22 | RT MBU ARD 07 22 | DC..0702.. | 22 | 25.00 | 2.30 | 42.60 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 17 | RT MBU ALC 12 32 | RT MBU ARC 12 32 | CC..1204.. | 32 | 33.30 | 1.00 | 60.60 | RTMS32 | M4.5 | T20/3MM | RTS32 |

| 18 | RT MBU ALT 16 32 | RRT MBU ART 16 32 | TC..16T3.. | 32 | 33.30 | 1.20 | 60.60 | RTMS32 | M3.5 | T15/3MM | RTS32 |

| 19 | RT MBU ALTP 16T3 32 | RT MBU ARTP 16T3 32 | TP..16T3.. | 32 | 33.30 | 1.20 | 60.60 | RTMS32 | M3.5 | T15/3MM | RTS32 |

| 20 | RT MBU ALTP 1604 32 | RT MBU ARTP 1604 32 | TP..1604.. | 32 | 33.30 | 1.20 | 60.60 | RTMS32 | M4.0 | T15/3MM | RTS32 |

- Micro Bore Units are delivered with all required spares such as insert screw, mounting screws, spanner, torx keys & allen keys.

- Inserts are not included with Micro Bore Units.

- Spares sold separately as well and can be ordered as per the ordering code shown in above table.

- Minimum diameter (Dmin) calculated based on 0.4mm insert nose radius.

- MBU variants with DC..0702.. insert are specially designed for close tolerance undercut applications.

- Maximum recommended material removal is 0.5mm diametrically.

- Customized MBU for special requirements can also be provided but will be made to order with a lead time of 3-6 weeks.

MBU - Straight Mounting Type

| Sr. No | Item Code | Insert | Db | L1 | F1 | Dmin | Mounting Screw | Insert Screw | Torx | Spanne | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| LH | RH | ||||||||||

| 1 | RT MBU SLW 02 14 | RT MBU SRW 02 14 | WC..0201.. | 14 | 11.0 | 4.1 | 22.0 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 2 | RT MBU SLC 04 14 | RT MBU SRC 04 14 | CC..04T0.. | 14 | 11.0 | 4.1 | 22.0 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 3 | RT MBU SRT 06T1 14 | RT MBU SRT 06T1 14 | TC..06T1.. | 14 | 11.0 | 4.1 | 22.0 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 4 | RT MBU SLT 0601 14 | RT MBU SRT 0601 14 | TC..0601.. | 14 | 11.0 | 4.1 | 22.0 | RTMS14 | M2.0 | T6/T8 | RTS14 |

| 5 | RT MBU SLC 06 16 | RT MBU SRC 06 16 | CC..0602.. | 16 | 13.3 | 5.1 | 27.6 | RTMS16 | M2.5 | T8/T10 | RTS16 |

| 6 | RT MBU SLT 06T1 16 | RT MBU SRT 06T1 16 | TC..06T1.. | 16 | 13.3 | 4.1 | 27.1 | RTMS16 | M2.0 | T6/T10 | RTS16 |

| 7 | RT MBU SLT 0601 16 | RT MBU SRT 0601 16 | TC..0601.. | 16 | 13.3 | 4.1 | 27.1 | RTMS16 | M2.0 | T6/T10 | RTS16 |

| 8 | RT MBU SLC 09 20 | RT MBU SRC 09 20 | CC..09T3.. | 20 | 18.3 | 7.2 | 37.1 | RTMS20 | M3.5 | T15/T10 | RTS20 |

| 9 | RT MBU SLT 09 20 | RT MBU SRT 09 20 | TC..0902.. | 20 | 18.3 | 6.3 | 37.1 | RTMS20 | M2.2 | T7/T10 | RTS20 |

| 10 | RT MBU SLTP 09 20 | RT MBU SRTP 09 20 | TP..0902.. | 20 | 18.3 | 6.3 | 37.1 | RTMS20 | M2.5 | T8/T10 | RTS20 |

| 11 | RT MBU SLD 07 20 | RT MBU SRD 07 20 | DC..0702.. | 20 | 18.3 | 6.3 | 37.1 | RTMS20 | M2.5 | T8/T10 | RTS20 |

| 12 | RT MBU SLC 09 22 | RT MBU SRC 09 22 | CC..09T3.. | 22 | 22.1 | 7.2 | 49.1 | RTMS22 | M3.5 | T15 | RTS22 |

| 13 | RT MBU SLT 1102 22 | RT MBU SRT 1102 22 | TC..1102.. | 22 | 22.1 | 7.2 | 49.1 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 14 | RT MBU SLT 1103 22 | RT MBU SRT 1103 22 | TC..1103.. | 22 | 22.1 | 7.2 | 49.1 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 15 | RT MBU SLTP 11 22 | RT MBU SRTP 11 22 | TP..1103.. | 22 | 22.1 | 7.2 | 49.1 | RTMS22 | M3.0 | T10/T15 | RTS22 |

| 16 | RT MBU SLD 07 22 | RT MBU SRD 07 22 | DC..0702.. | 22 | 22.1 | 7.2 | 49.1 | RTMS22 | M2.5 | T8/T15 | RTS22 |

| 17 | RT MBU SLC 12 32 | RT MBU SRC 12 32 | CC..1204.. | 32 | 32 | 10.3 | 69.6 | RTMS32 | M4.5 | T20/3MM | RTS32 |

| 18 | RT MBU SLT 16 32 | RT MBU SRT 16 32 | TC..16T3.. | 32 | 32 | 10.3 | 69.6 | RTMS32 | M3.5 | T15/3MM | RTS32 |

| 19 | RT MBU SLTP 16T3 32 | RT MBU SRTP 16T3 32 | TP..16T3.. | 32 | 32 | 10.3 | 69.6 | RTMS32 | M3.5 | T15/3MM | RTS32 |

| 20 | RT MBU SLTP 1604 32 | RT MBU SRTP 1604 32 | TP..1604.. | 32 | 32 | 10.3 | 69.6 | RTMS32 | M4.0 | T15/3MM | RTS32 |

Customized Micro Bore Units

- Customized Micro Bore Unit designed and manufactured at Renuka Tools® for grooving application.

- Customized boring bar also designed and manufactured at Renuka Tools ® for this special application.

ID Boring Application using Micro Bore Units

- Customized Micro Bore Unit designed and manufactured at Renuka Tools® for grooving application.

- Customized boring bar also designed and manufactured at Renuka Tools ® for this special application.

Mounting Dimensions for Micro Bore Units

Specification Chart

| Detail | Sr.No. | DbH7 | d1 | d2 | d3 | h3 | h4 | h5 | Th | hc | T |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1 | 14.0 | 16.0 | 3.7 | 2.7 | 9.3 | 2.8 | 1.2 | 8.0 | 8.65 ±0.02 | M2.5 |

| 2 | 16.0 | 19.0 | 4.6 | 3.2 | 11.5 | 2.8 | 1.6 | 9.0 | 9.65 ±0.02 | M3.0 | |

| 3 | 20.0 | 25.0 | 4.6 | 3.2 | 15.5 | 4.0 | 1.6 | 9.0 | 12.50 ±0.05 | M3.0 | |

| 4 | 22.0 | 30.0 | 6.5 | 4.3 | 24.0 | 5.0 | 1.8 | 13.0 | 15.40 ±0.05 | M4.0 | B | 5 | 32.0 | 46.0 | 11.9 | 5.4 | 33.0 | 6.3 | - | 16.0 | 23.00 ±0.05 | M5.0 |

- Position of the mounting holes mentioned above are for LH cutting Hand. For RH cutting hand, they will be mirrored.

- Mounting details mentioned in the above table depend on the bush diameter (Db) of the Micro Bore Unit.

- Please refer to the tables in the tabs of 'Angular Mounting Type' and 'Straight Mounting Type' to find the Bush Diameter (Db) of yours selected Micro Bore Unit.

FBU – Angular Mounting Type

Specification Chart – For Angular Mounting:

| Sr.No | Db | RT MBU ITEM CODE | INSERTS | D min | D2 | Bmin | h1max | Smin | S1mean | -ve range (radial) | +ve range (radial) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LH | RH | |||||||||||

| 1 | 11.11 | RT FBU ALT 06T1 11 | RT FBU ART 06T1 11 | TC..06T104 | 19 | 17 | 0.84 | 1 | 8.6 | 8.8 | 0.16 | 0.84 |

| 2 | 11.11 | RT FBU ALT 0601 11 | RT FBU ART 0601 11 | TC..06T104 | 19 | 17 | 0.84 | 1 | 8.6 | 8.8 | 0.16 | 0.84 |

| 3 | 15.08 | RT FBU ALC 06 15 | RT FBU ARC 06 15 | CC..060204 | 25 | 23 | 0.678 | 1.1 | 11.325 | 11.7 | 0.3 | 0.8 |

| 4 | 15.08 | RT FBU ALT 09 15 | RT FBU ART 09 15 | TC..090204 | 25 | 23 | 0.678 | 1.1 | 11.325 | 11.7 | 0.3 | 0.8 |

| 5 | 15.08 | RT FBU ALTP 09 15 | RT FBU ARTP 09 15 | TP..090204 | 25 | 23 | 0.678 | 1.1 | 11.325 | 11.7 | 0.3 | 0.8 |

| 6 | 19.05 | RT FBU ALC 09 19 | RT FBU ARC 09 19 | CC..09T304; | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 7 | 19.05 | RT FBU ALT 1102 19 | RT FBU ART 1102 19 | TC..110204 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 8 | 19.05 | RT FBU ALT 1103 19 | RT FBU ART 1103 19 | TC..110304 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 9 | 19.05 | RT FBU ALTP 11 19 | RT FBU ARTP 11 19 | TP..110304 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 10 | 19.05 | RT FBU ALTN 11 19 | RT FBU ARTN 11 19 | TP..110304 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 11 | 19.05 | RT FBU ALD 07 19 | RT FBU ARD 07 19 | DC..070204 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 12 | 22.225 | RT FBU ALC 09 222 | RT FBU ARC 09 222 | CC..09T304 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 13 | 22.225 | RT FBU ALT 1102 222 | RT FBU ART 1102 222 | TC..110204 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 14 | 22.225 | RT FBU ALT 1103 222 | RT FBU ART 1103 222 | TC..110304 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 15 | 22.225 | RT FBU ALTP 11 222 | RT FBU ARTP 11 222 | TP..110304 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 16 | 22.225 | RT FBU ALTN 11 222 | RT FBU ARTN 11 222 | TP..110304 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 17 | 22.225 | RT FBU ALD 07 222 | RT FBU ARD 07 222 | DC..070204 | 47 | 44 | 1.098 | 2.7 | 17.6 | 18.35 | 0.6 | 2.1 |

| 18 | 31.75 | RT FBU ALC 12 31 | RT FBU ARC 12 31 | CC..120404 | 73 | 70 | 0.776 | 4.2 | 27.125 | 28 | 0.7 | 3.5 |

| 19 | 31.75 | RT FBU ALT 16 31 | RT FBU ART 16 31 | TC..16T304 | 73 | 70 | 0.776 | 4.2 | 27.125 | 28 | 0.7 | 3.5 |

| 20 | 31.75 | RT FBU ALTP 16T3 31 | RT FBU ARTP 16T3 31 | TP..16T304 | 73 | 70 | 0.776 | 4.2 | 27.125 | 28 | 0.7 | 3.5 |

| 21 | 31.75 | RT FBU ALTP 1604 31 | RT FBU ARTP 1604 31 | TP..160404 | 73 | 70 | 0.776 | 4.2 | 27.125 | 28 | 0.7 | 3.5 |

| 22 | 31.75 | RT FBU ALTN 16 31 | RT FBU ARTN 16 31 | TN..160404 | 73 | 70 | 0.776 | 4.2 | 27.125 | 28 | 0.7 | 3.5 |

FBU – Straight Mounting Type

Specification Chart – For Straight Mounting:

| Sr.No | Db | RT MBU ITEM CODE | INSERTS | D min | D2 | Bmin | h1max | Smin | S1mean | -ve range (radial) | +ve range (radial) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LH | RH | |||||||||||

| 1 | 11.11 | RT FBU SLT 06T1 11 | RT FBU SRT 06T1 11 | TC..06T104 | 19 | 17 | 0.8 | 1.2 | 7.2 | 7.4 | 0.2 | 1 |

| 2 | 11.11 | RT FBU SLT 0601 11 | RT FBU SRT 0601 11 | TC..06T104 | 19 | 17 | 0.8 | 1.2 | 7.2 | 7.2 | 0.2 | 1 |

| 3 | 15.08 | RT FBU SLC 06 15 | RT FBU SRC 06 15 | CC..060204 | 25 | 23 | 0.7 | 1.5 | 10.5 | 10.8 | 0.3 | 1.2 |

| 4 | 15.08 | RT FBU SLT 09 15 | RT FBU SRT 09 15 | TC..090204 | 25 | 23 | 0.7 | 1.5 | 10.5 | 10.8 | 0.3 | 1.2 |

| 5 | 15.08 | RT FBU SLTP 09 15 | RT FBU SRTP 09 15 | TP..090204 | 25 | 23 | 0.7 | 1.5 | 10.5 | 10.8 | 0.3 | 1.2 |

| 6 | 19.05 | RT FBU SLC 09 19 | RT FBU SRC 09 19 | CC..09T304; | 36 | 34 | 0.4 | 2.4 | 13.2 | 13.8 | 0.6 | 1.8 |

| 7 | 19.05 | RT FBU SLT 1102 19 | RT FBU SRT 1102 19 | TC..110204 | 36 | 34 | 0.4 | 2.4 | 13.2 | 13.8 | 0.6 | 1.8 |

| 8 | 19.05 | RT FBU SLT 1103 19 | RT FBU SRT 1103 19 | TC..110304 | 36 | 34 | 0.4 | 2.4 | 13.2 | 13.8 | 0.6 | 1.8 |

| 9 | 19.05 | RT FBU SLTP 11 19 | RT FBU SRTP 11 19 | TP..110304 | 36 | 34 | 0.4 | 2.4 | 13.2 | 13.8 | 0.6 | 1.8 |

| 10 | 19.05 | RT FBU SLTN 11 19 | RT FBU SRTN 11 19 | TP..110304 | 36 | 34 | 0.598 | 1.7 | 14.4 | 14.9 | 0.4 | 1.3 |

| 11 | 19.05 | RT FBU SLD 07 19 | RT FBU SRD 07 19 | DC..070204 | 36 | 34 | 0.4 | 2.4 | 13.2 | 13.8 | 0.6 | 1.8 |

| 12 | 22.225 | RT FBU SLC 09 222 | RT FBU SRC 09 222 | CC..09T304 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 13 | 22.225 | RT FBU SLT 1102 222 | RT FBU SRT 1102 222 | TC..110204 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 14 | 22.225 | RT FBU SLT 1103 222 | RT FBU SRT 1103 222 | TC..110304 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 15 | 22.225 | RT FBU SLTP 11 222 | RT FBU SRTP 11 222 | TP..110304 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 16 | 22.225 | RT FBU SLTN 11 222 | RT FBU SRTN 11 222 | TP..110304 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 17 | 22.225 | RT FBU SLD 07 222 | RT FBU SRD 07 222 | DC..070204 | 47 | 44 | 0.8 | 3.6 | 16 | 16.7 | 0.7 | 2.9 |

| 18 | 31.75 | RT FBU SLC 12 31 | RT FBU SRC 12 31 | CC..120404 | 73 | 70 | 0.5 | 5.6 | 24 | 25 | 1 | 4.6 |

| 19 | 31.75 | RT FBU SLT 16 31 | RT FBU SRT 16 31 | TC..16T304 | 73 | 70 | 0.5 | 5.6 | 24 | 25 | 1 | 4.6 |

| 20 | 31.75 | RT FBU SLTP 16T3 31 | RT FBU SRTP 16T3 31 | TP..16T304 | 73 | 70 | 0.5 | 5.6 | 24 | 25 | 1 | 4.6 |

| 21 | 31.75 | RT FBU SLTP 1604 31 | RT FBU SRTP 1604 31 | TP..160404 | 73 | 70 | 0.5 | 5.6 | 24 | 25 | 1 | 4.6 |

| 22 | 31.75 | RT FBU SLTN 16 31 | RT FBU SRTN 16 31 | TN..160404 | 73 | 70 | 0.5 | 5.6 | 24 | 25 | 1 | 4.6 |

Operating Instructions

Notes

- Mount the Fine Boring Unit properly in the finish boring tool supplied by Renuka Tools. This can be easily done by simply tightening the mounting screws in a proper manner (Pic.1). In case the tool is of any other brand ensure that the manufacturer adheres to the mounting instructions provided by Renuka Tools. Else, it might result in non-efficient working or even tool failure.

- Set the required diameter before clamping the tool on the machine, ideally on a tool pre-setter, or else with the help of a precise dial indicator (Pic.2). During this setting, ensure that any one scale marking on the FBU inner scale coincides exactly with the extreme end marking on the outer vernier scale. This will automatically match some other inner scale marking with the other extreme end of the outer vernier scale (Pic.3). This will help the user to quickly adjust after initial trial of tool.

- See if the desired results are obtained by running the tool on the machine. In case of any deviation in the desired results, kindly use the spanner for adjustment. For increasing the diameter, rotate in clockwise direction and for decreasing, rotate in counter-clockwise direction. One entire division movement of the inner FBU scale will give you 20 microns on diameter (i.e., 10 microns radially). Now use the vernier scale for adjustment. If the diameter reading has to be increased, kindly match the adjacent marking (of left side) with the nearest vernier scale marking. This will result in increase of 2 microns on the diameter (i.e., 1 micron radially) (Pic 3.1 - Zoomed). For reduction of diameter, follow the same procedure in the opposite direction (Pic 3.2 - Zoomed).

- Maximum diameter adjustment can be checked from the rear end of the spanner (Pic.4). Do not exceed the maximum limit as it may cause permanent damage to the unit.

Precautionary Measures

- Due to constraints in the assembly tolerances, it is recommended that units, if damaged, are returned to Renuka Tools for assessment/repair in a controlled environment. Commercials for repair can only be determined after detailed assessment of the damaged unit.

- Renuka Tools Micro Bore Unit cannot be adjusted beyond its range and the maximum range can be checked from the thickness of the end portion of the spanner provided along with the unit. Exceeding the range might result in permanent damage to the unit.

- Kindly change the mounting screws and insert screws ahead in time to avoid accidents.

- In case of any observed decrease in accuracy over the time of usage, kindly request Renuka Tools for servicing the unit.