Finish Boring Kit

Facts & Advantages

- Used for finish boring application from diameter 6mm to 205mm with a least count of 10 microns radially.

- Available with options of selecting one or many boring bars & different adaptors depending on requirement.

- User friendly & quick assembly & quick adjustment ensures minimum loss time.

- Comes with fine adjustment setting ensuring zero backlash.

- Most economic solution for the complete range of diameters for finish boring application.

- Ideal finish boring tool for tool - room set-ups.

- Apart from standard product range, tailor made boring heads & adaptors are also available on demand.

- Assembly Details

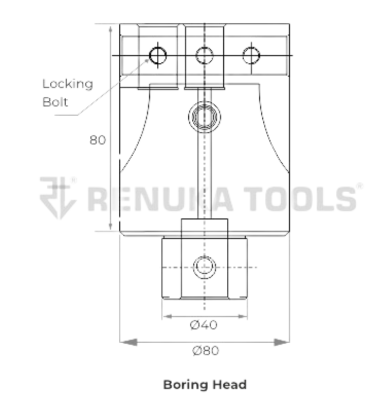

- Boring Head

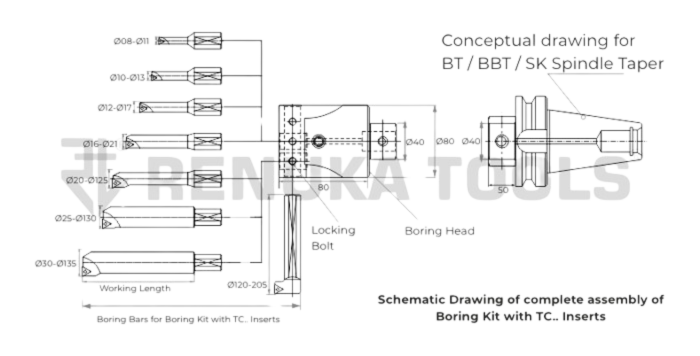

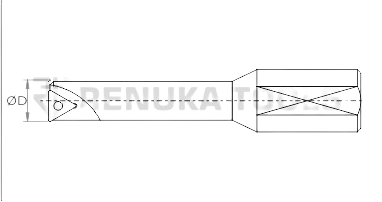

- Boring Bars For TC.. Inserts

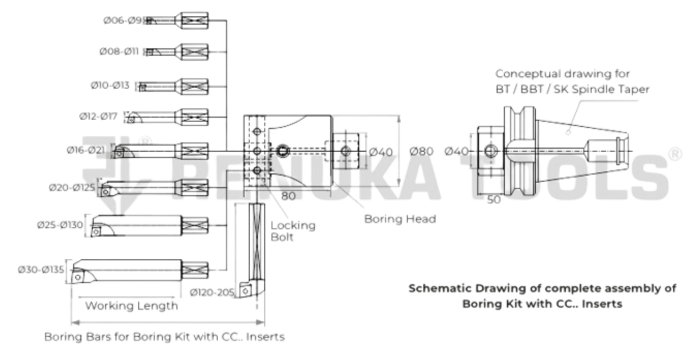

- Boring Bars For CC.. Inserts

- Adaptors for Boring Kit

- Operating Instructions

- Precautionary Measures

Assembly Details

Boring Head For Boring Kit

Specification Chart

| Sr. No | Item Code | Diameter Range | Least Count | Boring Bar Clamping Screw (Qty) | Boring Head Locking Bolt | Allen Keys |

|---|---|---|---|---|---|---|

|

1 |

RT BH 6-205 |

6-205 |

10 microns |

M8 (3) |

M10 |

4mm / 8mm |

Notes

- Spares for Boring Head will be provided along with the Boring Head.

- If required additionally, all spares can be orderd seperately as well.

- Required Boring Bars to be orderd seperately.

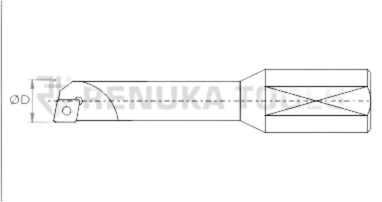

Boring Bars for Boring Kit For TC.. Inserts

Specification Chart

| Sr. No | Item Code | Insert | Diameter Range

Ømin - Ømax D |

Working Length |

|---|---|---|---|---|

|

1 |

RT BKBBT 0811 |

TC.. 06T1 |

8-11 |

32 |

|

2 |

RT BKBBT 1013 |

TC.. 06T1 |

10-13 |

40 |

|

3 |

RT BKBBT 1217 |

TC.. 0902 |

12-17 |

53 |

|

4 |

RT BKBBT 1621 |

TC.. 0902 |

16-21 |

68 |

|

5 |

RT BKBBT 20125 |

TC.. 1102 |

20-125 |

83 |

|

6 |

RT BKBBT 25130 |

TC.. 1102 |

25-130 |

96 |

|

7 |

RT BKBBT 30135 |

TC.. 1102 |

30-135 |

115 |

|

8 |

RT BKBBT 120205 |

TC.. 1102 |

120-205 |

85 |

Notes

- Insert Screws and Torx keys will be provided along with the Boring Bars. Inserts not included.

- If required additionally, all spares can be ordered separately as well.

- Diameter range ‘D’ calculated considering 0.4mm insert nose radius

- Maximum recommended material removal is 0.5mm diametrically.

- Customized boring bars can also be provided but will be made to order with lead time of 3-6 weeks.

- Please refer the table below these notes for the spare details.

Spare Details

| Sr. No | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

TC.. 06T1 |

M2 |

T-6 |

|

2 |

TC.. 0902 |

M2.2 |

T-6 |

|

3 |

TC.. 1102 |

M2.5 |

T-7 |

Boring Bars for Boring Kit For CC.. Inserts

Specification Chart

| Sr. No | Item Code | Insert | Diameter Range

Ømin - Ømax D |

Working Length |

|---|---|---|---|---|

|

1 |

RT BKBBC 0609 |

CC.. 0400 |

6-9 |

26 |

|

2 |

RT BKBBC 0811 |

CC.. 0602 |

8-11 |

32 |

|

3 |

RT BKBBC 1013 |

CC.. 0602 |

10-13 |

40 |

|

4 |

RT BKBBC 1217 |

CC.. 0602 |

12-17 |

53 |

|

5 |

RT BKBBC 1621 |

CC.. 09T3 |

16-21 |

68 |

|

6 |

RT BKBBC 20125 |

CC.. 09T3 |

20-125 |

83 |

|

7 |

RT BKBBC 25130 |

CC.. 09T3 |

25-130 |

96 |

|

8 |

RT BKBBC 30135 |

CC.. 1204 |

30-135 |

115 |

|

9 |

RT BKBBC 120205 |

CC.. 1204 |

120-205 |

85 |

Notes

- Insert Screws and Torx keys will be provided along with the Boring Bars. Inserts not included.

- If required additionally, all spares can be ordered separately as well.

- Diameter range ‘D’ calculated considering 0.4mm insert nose radius

- Maximum recommended material removal is 0.5mm diametrically.

- Customized boring bars can also be provided but will be made to order with lead time of 3-6 weeks.

- Please refer the table below these notes for the spare details.

Spare Details

| Sr. No | Insert | Insert Screw | Torx |

|---|---|---|---|

|

1 |

CC.. 0400 |

M2 |

T-6 |

|

2 |

CC.. 0602 |

M2.5 |

T-7 |

|

3 |

CC.. 09T3 |

M3.5 |

T-15 |

|

4 |

CC.. 1204 |

M4.5 |

T-20 |

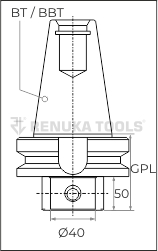

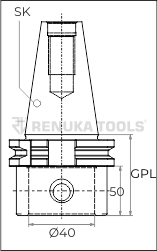

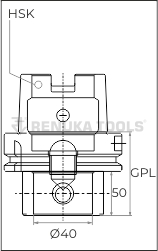

Adaptor Details for Boring Kit

Specification Chart

| Sr. No | Item Code | Spindle Taper | GPL of Adaptor | Stock |

|---|---|---|---|---|

|

1 |

ADP BT40 40 |

BT40 |

77.0 |

|

|

2 |

ADP BT50 40 |

BT50 |

88.0 |

|

|

3 |

ADP BBT40 40 |

BBT40 |

75.0 |

|

|

4 |

ADP BBT50 40 |

BBT50 |

85.0 |

|

|

5 |

ADP SK40 40 |

SK40 |

69.1 |

|

|

6 |

ADP SK50 40 |

SK50 |

69.1 |

|

|

7 |

ADP ISO40 40 |

ISO40 |

60.0 |

|

|

8 |

ADP ISO50 40 |

ISO50 |

62.0 |

|

|

9 |

ADP ISO60 40 |

ISO60 |

66.0 |

|

|

10 |

ADP HSKA50 40 |

HSKA50 |

76.0 |

|

|

11 |

ADP HSKA63 40 |

HSKA63 |

76.0 |

|

|

12 |

ADP HSKA80 40 |

HSKA80 |

76.0 |

|

|

13 |

ADP HSKA100 40 |

HSKA100 |

79.0 |

|

Notes

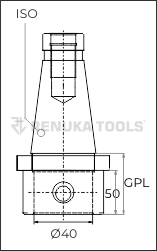

- Diameter of Adaptor ID for all of the above is 40mm.

- Working Length for all of the above is 50mm.

- Special Adaptor Bolt item code RTABM840 will be provided along with the Adaptors and if required additionally, can be ordered separately as well.

- Customized adaptors for any other spindle taper can also be provided but will be made to order with lead time of 3-6 weeks.

- In the above table, denotes ready in stock and denotes lead time of 2-3 weeks.

Operating Instructions

- The boring head is initially set on minimum mark on the scale.

- Follow below instructions to assemble the boring kit: a) Clamp the required boring bar on to the boring head with the help of the clamping screws provided with the boring head. b) Clamp the adaptor on to the boring head with the special adaptor bolts provided with the adaptor.

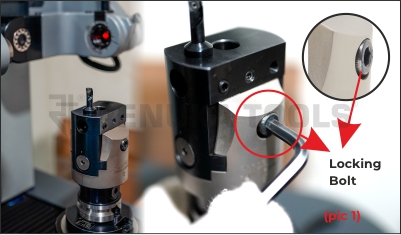

- In case you wish to adjust the diameter, loosen the Locking Screw of M10 with the provided Allen key of 8mm. (pic 1)

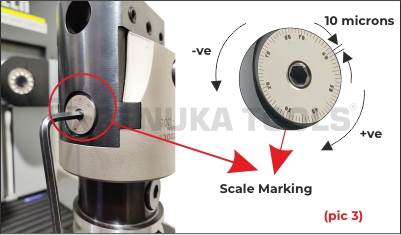

- Use the fine adjustment dial to set the required diameter. (pic 2)

- The smallest division is 10 microns and one rotation is 0.75mm radially, adjust accordingly and then recheck if the required size is achieved. (pic 3)

- If the required diameter is achieved, tighten the locking screw with a torque wrench (recommended) for precise repeatability and to ensure sufficient torque for locking. (pic 1)

- The tool is now ready to use.

- It is recommended to dismantle the boring kit and set to minimum after use, if to be stored for long period without use. (pic 4)

- To avoid damage due to rusting, ensure periodic lubrication.

Precautionary Measures

- Due to constraints in the assembly tolerances, it is recommended that tools, if damaged, are to be returned to Renuka Tools for assessment/repair in a controlled environment. Commercials for repair can only be determined after detailed assessment of the damaged tool.

- Please change the locking screws and insert screws ahead in time to avoid accidents.

- In case of any observed decrease in accuracy over the time of usage, please request Renuka Tools for servicing the tool.

- Ensure that the locking bolt is loosened before using fine adjustment to avoid internal damage to adjustment mechanism.